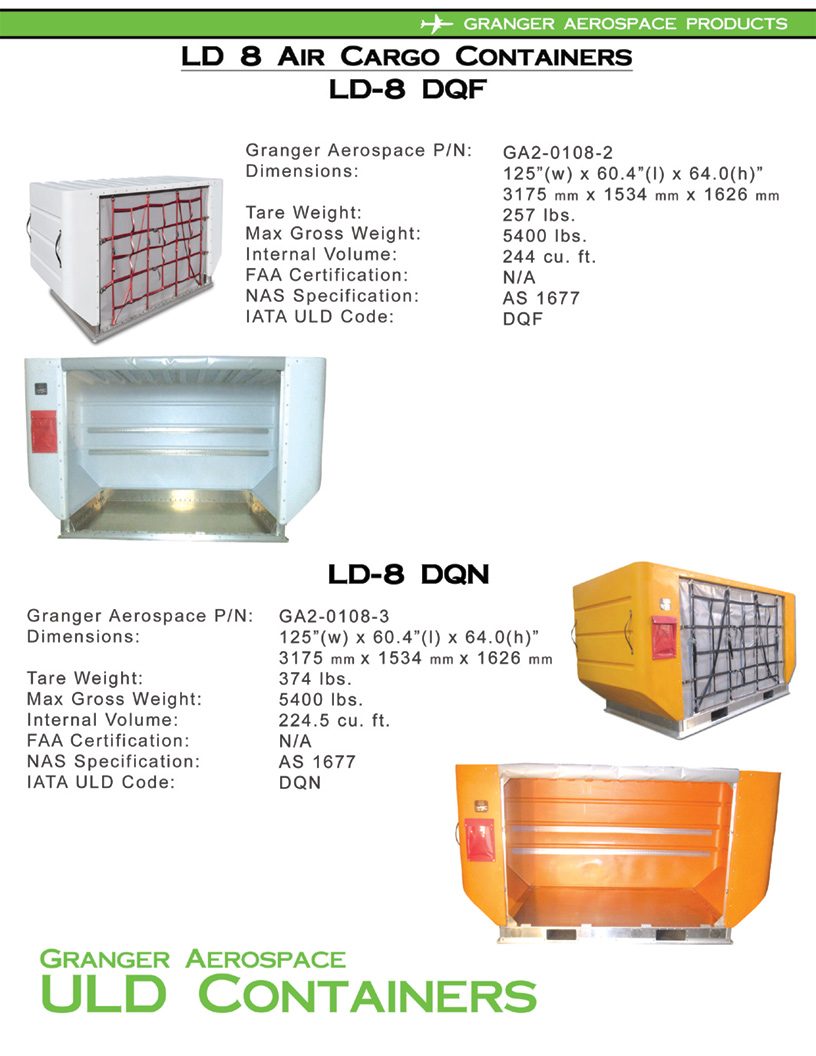

LD 8 Air Cargo Container Features

· Granger Aerospace Products Air Cargo Containers are the only cargo container manufactured from a combination of aluminum and durable LLDPE.

The LD-8 Body is weld-able

The Granger Aerospace Products Air Cargo Container is lighter than most standard containers.

Granger Aerospace Products cargo containers are robust.

No aluminum body panels to patch.

No aluminum body frames to replace.

Lighter weight, less down time and lower repair costs equals lower cost of ownership.

Enhanced Threshold.

Fewer fasteners to replace.

Unique design allows for faster repairs.

Less spare parts to keep in stock.

Granger Aerospace Products offers alternative solutions for your ULD needs.

It is our goal to offer our customer not only lower cost container but a trusted partnership for your company.

It’s our goal to offer more choices to our customers

Through or focus on technology and research, we are continually making improvements to our design.

Our customers save fuel by using robust as well as cost-efficient lightweight containers.

Aerospace & Rotational Molding

Granger's 25 years of industry leading custom rotational molding experience has allowed for the rotomoulding leader to provide high quality solutions for the defense & aerospace industry. Being the only rotational moulding company in the world with a FAA issued TSO C90d certificate of quality is an example of Granger's commitment to quality production for the Aerospace and defense industries.

Rotational Molding is a plastics manufacturing process that is primarily used to develop or produce hollow one-piece plastic products. Additionally called "rotomoulding", it is a reduced pressure, high temperature production method that integrates heat as well as bi-axial turning. Typically produced moulded components can include parts such as laundry carts, playground equipment, intermediate bulk containers, air cargo containers, secondary containments, tornado shelters, nuclear missile covers, shipping containers, bulk storage containers, plastic pallets and so much more.

Learn more about the rotomolding process by clicking here!

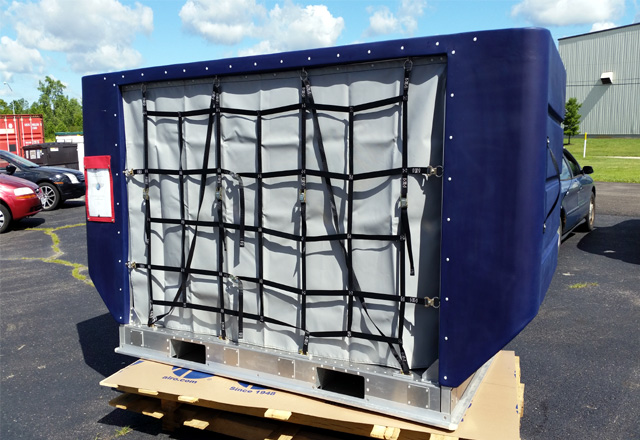

Custom Color LD 8 for Professional Football Team

Custom Color LD 8 for Professional Football Team